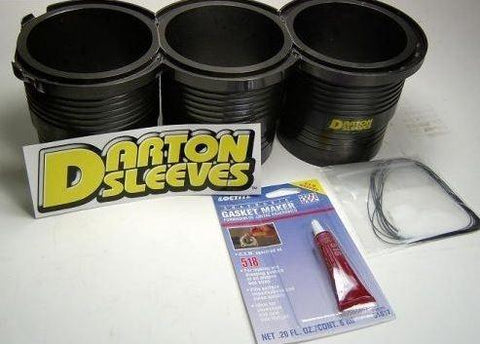

Darton Iron MID Wet Sleeves Subaru BRZ 2012-2015 / Scion FR-S 2012-2020 (800-890)

Give us a call to get the best prices and parts for your build. Or, just call us with a cool racing story...either way we're here.

Phone Call or Text 651-927-4510

Email - sales@maperformance.com

Call Or Text Our Experts at 651-927-4510

*SEE DETAILS