Honda L15B7 1.5T PCV System Testing and Observations

Objective: To understand operation and measure performance of 2017+ Honda Civic L15B7 OEM PCV and Air Separation systems to determine need for external catch can system.

Testing Procedure

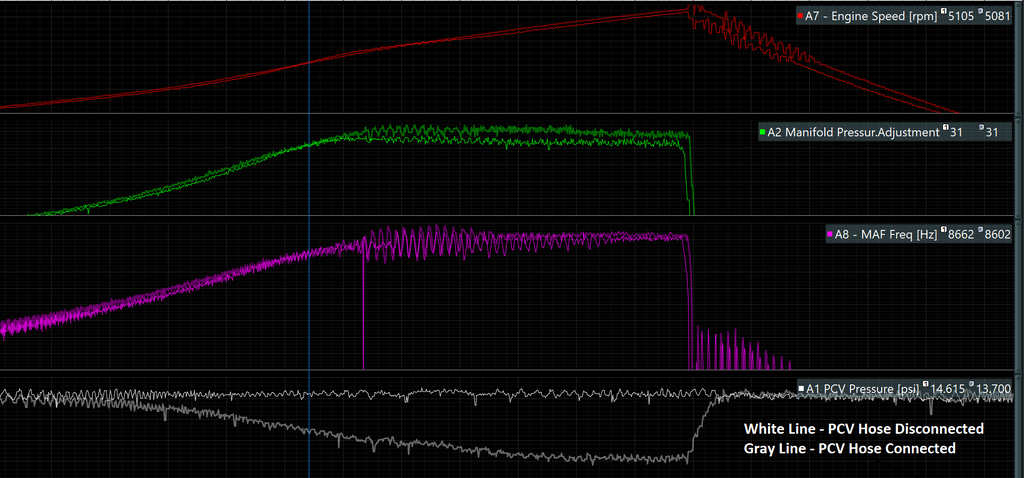

Dyno testing performed with our 2017 Honda Civic Si at various power levels, with a 1 bar pressure sensor installed in the oil fill cap on the valve cover. That pressure sensor recorded pressure in a zone/position where there was minimal fluid velocity, so as to get a proper reading of pressure underneath the valve cover. No concerns of localized pressure pocket or High/Low pressure zones. This pressure data was overlaid with general engine conditions to correlate differences in crankcase pressure (inferred from pressure underneath valve cover) with changes in power output.

Performed dyno test with turbo inlet PCV hose disconnected to observe crankcase pressure without a source of ventilation vacuum

General System Notes

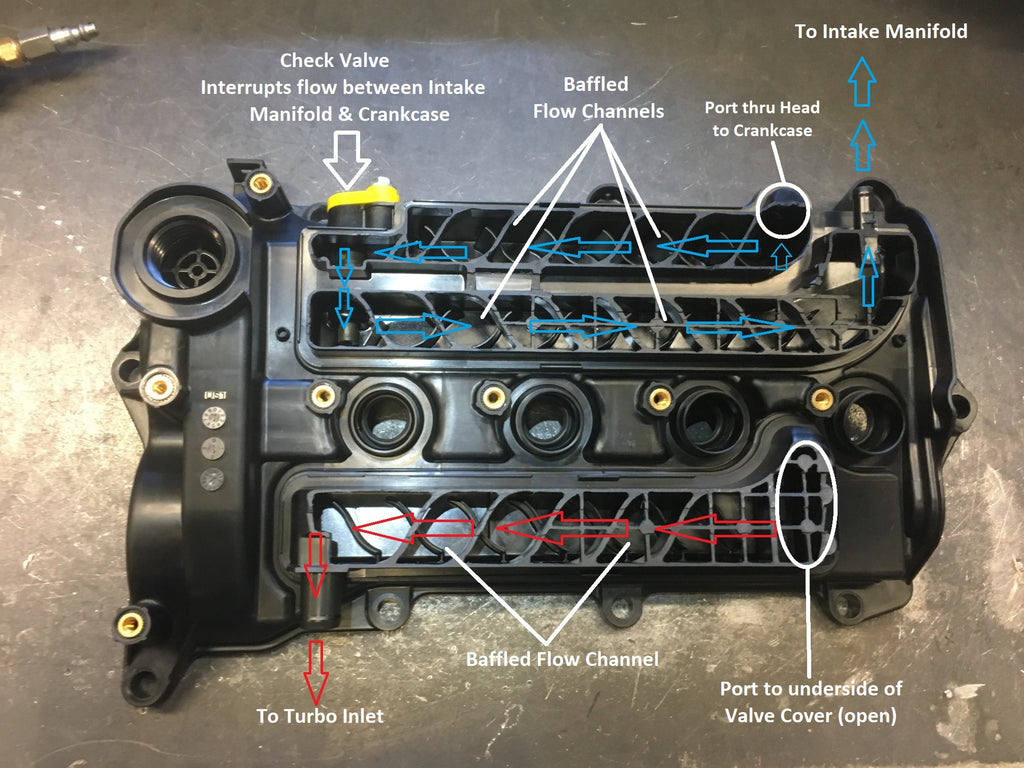

Two sources of ventilation for the crankcase: the Intake Manifold whilst under vacuum, and the turbo inlet tract whilst manifold is under boost. It is not confirmed at this time the amount of ventilation the turbo inlet tract provides whilst the manifold is under vacuum and with minimal low pressure provided by turbo inlet.

There is only one check valve in the entire system, which is located in the tract between intake manifold and crankcase.

No cyclonic separators; only baffled channels molded into the valve cover to separate oil vapor.

The stock system appears to do a very good job at air/oil vapor separation, as there are minimal traces of oil film on the intake/inlet tract, the compressor inlet, compressor outlet or charge system.

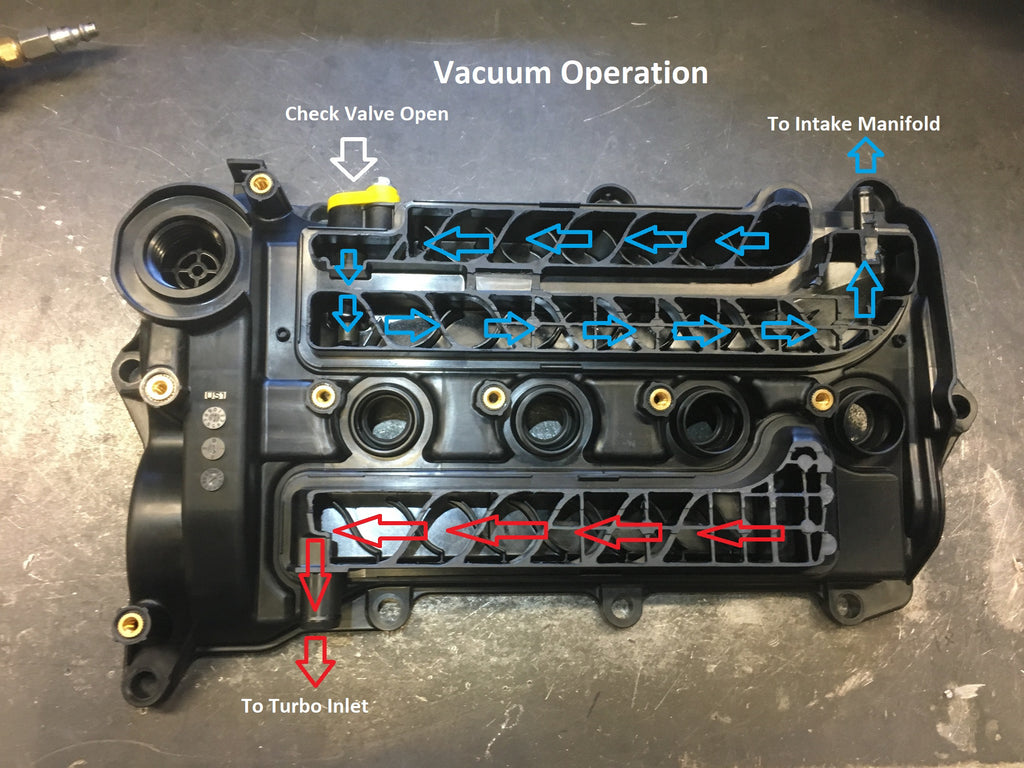

Honda 1.5T Vacuum Operation

Positive Crankcase Pressure is pulled into the Intake Manifold (vacuum) via a sealed port that connects the intake manifold directly to the crankcase. The port goes through the cylinder head, but does not pull from the area underneath the valve cover.

During the vacuum operation the sole check valve is open, however it only allows an extremely low flow rate. It is likely that this is because a significant flow rate under vacuum is not necessary, and by doing so they would also need to introduce additional/larger fresh air sources to the crankcase system.

**It is unclear/untested so far as to how much fresh air, if any, is pulled into the crankcase via the boost/turbo inlet channel

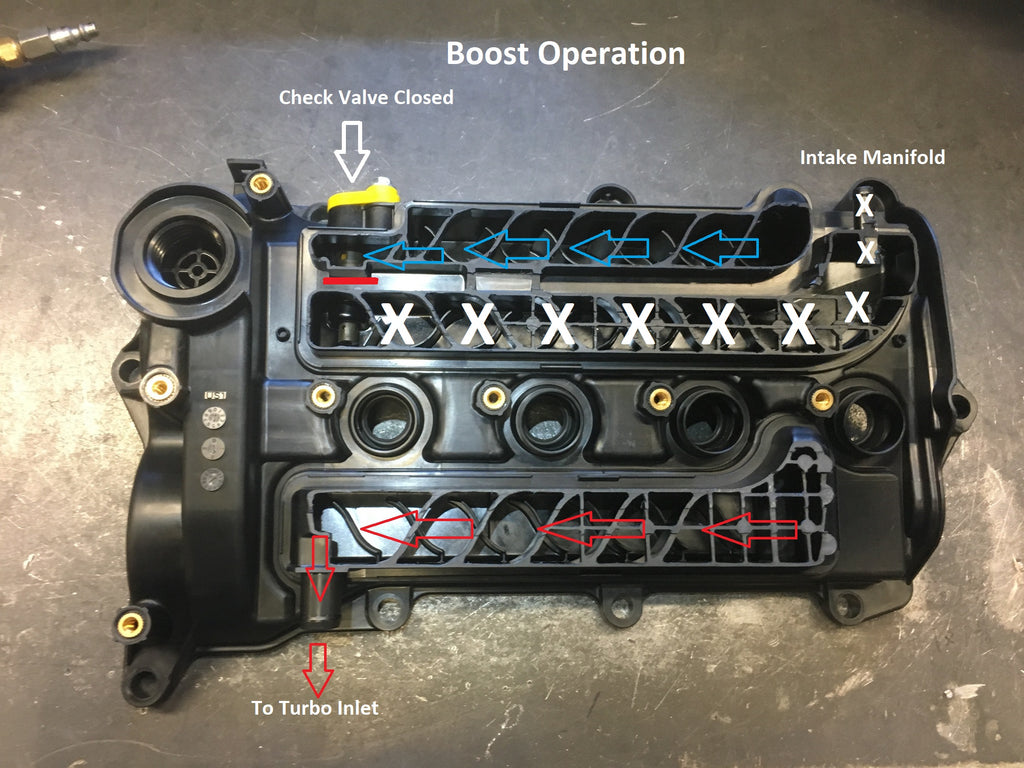

Boost Operation: What is happens internally to my 1.5T L15B7 while under boost?

Upon the Intake Manifold seeing positive pressure, the check valve between the intake manifold and crankcase closes, making the only ventilation source the turbo inlet.

During normal conditions/transient changes in pressure, the Check Valve closes and seals almost instantly. The only non-perfect behavior is on a bench when pressure is very slowly increased to the valve, in which case it doesn’t seal until 5-6psig.

There are three large "ports" which connect the area under the valve cover to the crankcase, evenly spaced along the engine.

The turbo inlet is a very, very effective supply of low pressure; and therefore the flow rate of the mass and volume of Crankcase Pressure is extremely high. Further, the more boost more mass flow through the turbo inlet (read: higher boost/power levels), the more crankcase pressure is able to be pulled from the crankcase and through the valve cover.

For reference, at the 300whp level (20psig), the turbo inlet is able to pull the crankcase pressure down to -.6psig. More remarkable is at the 400whp level (35psig), the turbo inlet is able to pull the crankcase pressure down to -1.5psig – way below atmospheric pressure! This is impressive because it shows the added crankcase pressure caused by increased piston blow-by is not proportional to the suction increase from the turbo inlet- quite impressive at double the horsepower on an engine that is stock from valve cover to oil pan.

Conclusion: Does your 2017+ Civic Si Need A Catch Can?

In stock longblock form we have found that the L15B7 found in the 2017+ Honda Civic Si PCV system works very well, and operates well beyond what we expected when beginning the testing. For this reason, we have decided to halt the current development on a catch can solution for the car to focus efforts elsewhere. As we make changes to the car and continue to up the power we will revisit along the way until we find a weak point!

Thank you for reading, if you have any questions at all please feel free to reach out to us as we are here to help!

651-348-8811

Comments (0)

There are no comments for this article. Be the first one to leave a message!