Today MAPerformance brings you a list of some of the most common issues you may run into with your SRT4 transmissions and share some of our best selling upgrade components!

Common issue #1 - Broken Shift Selector

The Fix - MAPerformance Billet Shift Selector

The MAP billet shift selector is a direct replacement for the brittle, cast component installed from the factory. Machined from 4140 chromoly that has been hardened to 50 HRC for the ultimate in strength and durability this shift selector will take anything you can throw at it and we include a one year warranty to back up that claim! If your stock piece hasn't failed yet, it's only a matter of time! Be proactive and preserve your peace of mind!

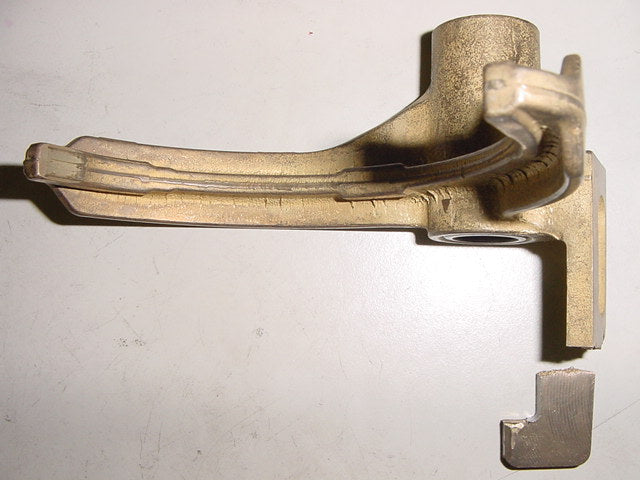

It may not be pretty, but it's strong!

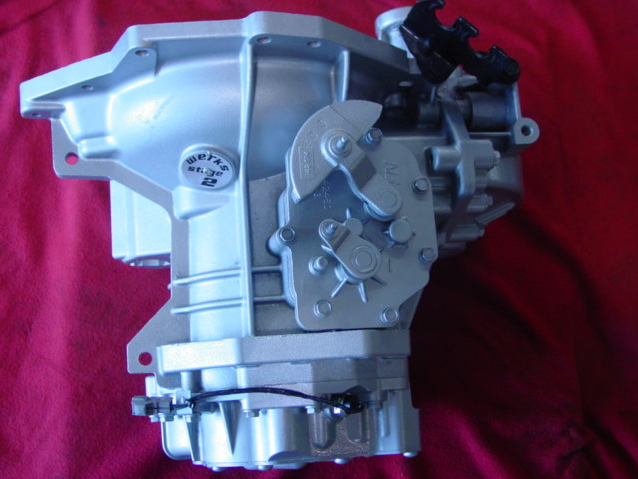

Issue #2 - Weak factory input shaft

The Fix - Billet Input Shaft / Straight Cut 1st and 2nd Gear

We have as an option on our rebuilds to add a Billet Heavy Duty input shaft which is known to withstand up to 1000hp in your SRT4 Transmission. As you can see in the pic, the factory unit has an area that is weak and can easily snap.

These Input Shafts are made of Forged 4320 high nickel chrome moly steel and rated to 1000hp, they come with a straight cut first gear (3.0 rataio)(daily drivable with the torque reduction and length of first to launch) and straight cut second gear.

Issue #3 - Shift Fork Breakage

The Fix - Billet Shift Fork

The OEM 3-4 shift fork in the SRT 4 Transmission is known to break at the shift shaft end when under hard and abusive shifting. The pic below is of a broken unit. In our Dodge Neon SRT-4 transmission rebuild we offer a billet shift fork option so you never have to worry about it again.

Common issue #3 - Hub Clip

The fix - SS Upgrade

These have the problem of coming undone and allowing the 3-4 hub to wander. All of our rebuild Neon SRT-4 units come with the new SS upgraded version so this will never be a problem again.

Common issue #3 - Synchro Ring Wear

The Fix - Proper Clutch Adjustment

It is common when a clutch is dragging at high RPM to burn up the 3rd gear synchro blocker ring. In the pic, this ring wore down so badly that it bottomed out on the gear. It then was unable to work properly and 3rd gear started to grind. You can see the scratches on the end next to the teeth from this. Proper clutch adjustment is critical for long synchro life. When you receive your trans back from us, there will be detailed instructions on how to prevent a clutch from dragging so this won’t happen again and your car will shift quickly and smoothly at high RPM as it was supposed to.

Comments (3)

How much does it cost to fix the synchro ring wear. I´m think about buying one thats in good shape but this is a problem it has.

Do you guys also offer the gear extenders ?

You still selling built transmissions? Werks web sit says they no longer service them.